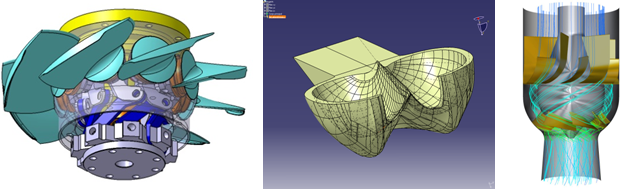

Conception hydraulique

La conception hydraulique de nos turbines s’appuie sur la démarche suivante :

- Redimensionnement, simplification et adaptation de la technique hydraulique des grandes turbines.

- Essai sur stand.

- Mesure de l’impact des adaptations et simplifications, de manière à optimiser le rapport performances/coûts de fabrication.

Dans le but de respecter le critère de simplicité, les machines proposées sont développées en faisant appel à un maximum d’éléments standards ou pouvant être fournis par des sous-traitants non spécialisés. Ce mode de faire favorise ainsi la production des équipements hydromécaniques à proximité de l’aménagement en construction.

Les machines proposées atteignent un rendement mécanique de l’ordre de 90%, celui-ci étant garanti par les résultats d’essais et les certificats correspondants. Le Maître de l’ouvrage est ainsi libéré des essais de performance sur site et peut déterminer d’emblée, avec certitude, la rentabilité financière de son aménagement.

Le développement des gammes de machines en laboratoire garantissant la tenue des performances annoncées, les conséquences dommageables du non-respect des garanties sont évitées, aussi bien pour l’exploitant que pour le constructeur.

Les résultats de cette recherche sont mis à disposition de quiconque en fait la demande et ceci sans exclusivité. En contrepartie, une participation aux frais de développement du type de machine et d’adaptation aux besoins du client est demandée.

Sur la base des données communiquées par le client, le laboratoire fournit toutes les indications nécessaires à la réalisation de la machine, telles que :

- Le type de turbine.

- Les courbes de rendement et de puissance mécanique en fonction du débit.

- Les vitesses de rotation nominale et d’emballement.

- Les efforts sur la roue et son aubage.

- La hauteur d’aspiration maximale, pour les turbines à réaction.

- Le profil hydraulique complet de la turbine et de sa roue.